In the fast-paced world of semiconductor manufacturing, the choice of substrate material can make all the difference in achieving optimum performance and efficiency. That's where silicon nitride substrates come into play. By incorporating silicon nitride, a versatile compound known for its excellent thermal, mechanical, and electrical properties, manufacturers can reap a host of advantages.

One major advantage of using silicon nitride substrates is their superior thermal conductivity. Heat dissipation is a critical consideration in semiconductor manufacturing, as excessive heat can lead to performance degradation and even component failure. With their high thermal conductivity, silicon nitride substrates efficiently transfer heat away from sensitive components, ensuring optimal operating conditions and increased overall reliability.

Another benefit of silicon nitride substrates is their exceptional mechanical strength. These substrates are robust and resistant to thermal shocks and mechanical stresses, making them suitable for a wide range of applications. From high-frequency circuits to power devices, silicon nitride substrates offer enhanced durability, reducing the risk of failure and prolonging the lifespan of semiconductor components.

In addition to their thermal and mechanical properties, silicon nitride substrates also exhibit excellent dielectric properties, superb chemical resistance, and minimal electrical leakage. This combination of characteristics makes them ideal for various semiconductor manufacturing processes, ensuring enhanced performance and superior product quality.

When it comes to semiconductor manufacturing, the advantages of using silicon nitride substrates are plentiful. From improved thermal management to enhanced durability and performance, incorporating silicon nitride into the production process can yield significant benefits.

Properties of Silicon Nitride Substrates

Silicon nitride is a versatile compound that exhibits a wide array of beneficial properties that are highly desirable in semiconductor manufacturing. One of the key properties of silicon nitride substrates is their excellent thermal conductivity. Thermal conductivity refers to the ability of a material to conduct heat efficiently. In semiconductor devices, effective heat dissipation is essential to prevent overheating and maintain optimal operating conditions. Silicon nitride substrates excel in thermal management, allowing for the efficient transfer of heat away from sensitive components.

In addition to thermal conductivity, silicon nitride substrates also possess remarkable mechanical strength. Mechanical strength is crucial in semiconductor manufacturing to withstand thermal shocks, mechanical stresses, and other environmental factors. Silicon nitride substrates exhibit high resistance to mechanical damage, ensuring the durability and longevity of semiconductor components. This robustness makes silicon nitride substrates suitable for diverse applications, from high-frequency circuits to power devices, where reliability is paramount.

Furthermore, silicon nitride substrates demonstrate excellent dielectric properties, offering high electrical insulation and low dielectric constant. Low dielectric constant is advantageous in reducing signal distortion and improving the performance of semiconductor devices. The superior dielectric properties of silicon nitride substrates contribute to enhanced electrical performance and overall reliability in semiconductor applications. Additionally, silicon nitride substrates exhibit superb chemical resistance, ensuring stability and consistency in various manufacturing environments.

Advantages of Using Silicon Nitride Substrates in Semiconductor Manufacturing

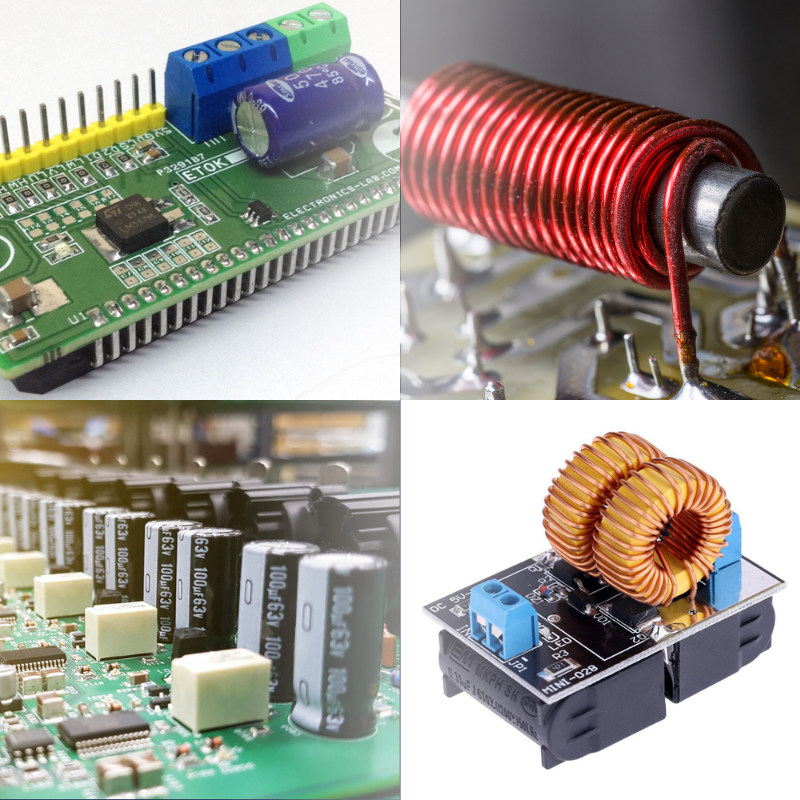

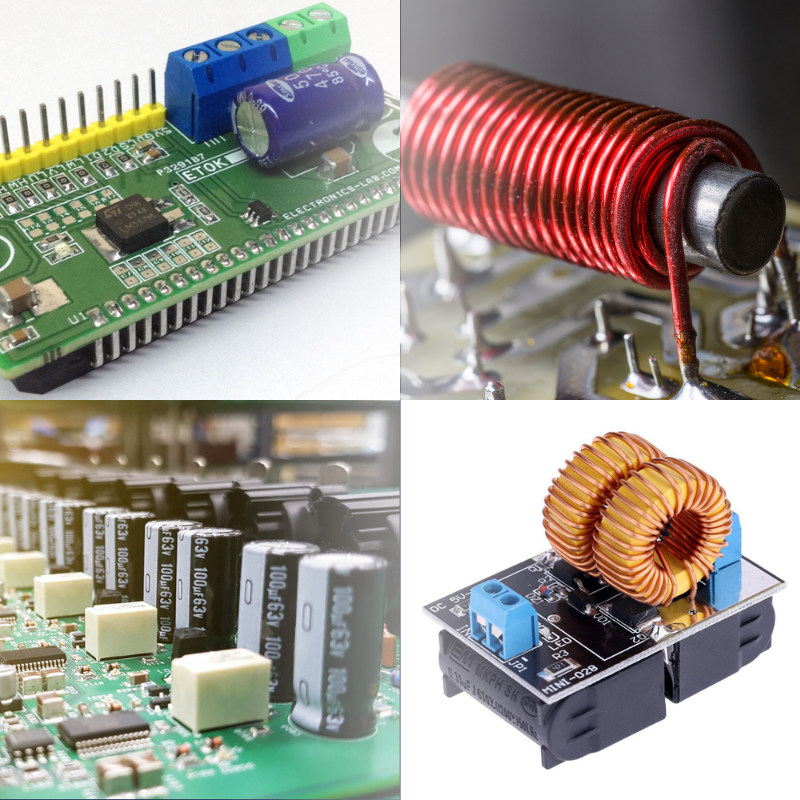

The adoption of silicon nitride substrates in semiconductor manufacturing brings about a multitude of advantages that contribute to improved performance, reliability, and efficiency of semiconductor devices. One significant advantage of using silicon nitride substrates is their enhanced thermal stability and reliability. Silicon nitride substrates efficiently dissipate heat, preventing overheating and maintaining optimal operating temperatures. This thermal stability enhances the longevity and performance of semiconductor components, reducing the risk of failure and ensuring consistent operation.

Another advantage of silicon nitride substrates is their low dielectric constant and high electrical insulation properties. These characteristics enable precise signal transmission, minimize signal loss, and enhance the overall electrical performance of semiconductor devices. By reducing electrical leakage and signal distortion, silicon nitride substrates play a vital role in improving the efficiency and reliability of semiconductor products.

Moreover, silicon nitride substrates offer compatibility with various deposition techniques commonly used in semiconductor manufacturing processes. The versatility of silicon nitride substrates allows for seamless integration into different fabrication methods, enabling manufacturers to achieve precise control over the deposition and patterning of semiconductor materials. This compatibility enhances the manufacturing flexibility and efficiency, leading to the production of high-quality semiconductor devices with enhanced performance.

Furthermore, the improved mechanical strength and resistance to stress exhibited by silicon nitride substrates contribute to the durability and reliability of semiconductor components. These substrates can withstand harsh operating conditions, mechanical shocks, and thermal cycling, ensuring the long-term performance and functionality of semiconductor devices. The robust nature of silicon nitride substrates enhances the structural integrity of semiconductor products, reducing the risk of failure and increasing the overall product lifespan.

Case Studies and Success Stories of Using Silicon Nitride Substrates

Several case studies and success stories showcase the benefits and effectiveness of using silicon nitride substrates in semiconductor manufacturing. One notable example is the application of silicon nitride substrates in high-power electronic devices, such as power amplifiers and RF transistors. Silicon nitride substrates have been instrumental in improving the thermal management and reliability of these devices, leading to enhanced performance and reduced failure rates.

Another success story involves the use of silicon nitride substrates in high-frequency communication systems, where signal integrity and reliability are critical. Silicon nitride substrates have enabled manufacturers to achieve high-speed signal transmission, low signal loss, and exceptional electrical performance in these applications. The use of silicon nitride substrates has significantly contributed to the advancement of communication technologies, ensuring reliable and efficient signal processing.

Additionally, silicon nitride substrates have found widespread adoption in the production of advanced sensors and MEMS devices due to their superior thermal, mechanical, and electrical properties. These substrates have enabled the development of highly sensitive and reliable sensors for various applications, ranging from automotive systems to medical devices. The use of silicon nitride substrates has revolutionized sensor technology, offering enhanced performance, durability, and accuracy in sensing applications.

These case studies and success stories highlight the diverse applications and benefits of using silicon nitride substrates in semiconductor manufacturing. The exceptional properties of silicon nitride substrates have proven instrumental in enhancing the performance, reliability, and efficiency of semiconductor devices across different industries and applications. The success stories demonstrate the significant impact of silicon nitride substrates on advancing semiconductor technology and driving innovation in the field.

Conclusion

The Future of Silicon Nitride Substrates in Semiconductor Manufacturing

In conclusion, the advantages of using silicon nitride substrates in semiconductor manufacturing are undeniable. The exceptional thermal conductivity, mechanical strength, dielectric properties, and compatibility of silicon nitride substrates make them an ideal choice for achieving high-performance semiconductor devices. By incorporating silicon nitride substrates into the manufacturing process, companies can benefit from enhanced thermal stability, improved electrical performance, and increased reliability of semiconductor products.

The future of silicon nitride substrates in semiconductor manufacturing looks promising, with continued advancements and innovations in materials science and fabrication techniques. As the demand for high-performance semiconductor devices grows, silicon nitride substrates are poised to play a crucial role in meeting these requirements. The versatility and effectiveness of silicon nitride substrates make them a valuable asset for semiconductor manufacturers looking to enhance product quality, performance, and reliability.

Overall, the use of silicon nitride substrates offers a competitive edge in semiconductor manufacturing, enabling companies to produce cutting-edge devices with superior performance and durability. By harnessing the benefits of silicon nitride substrates, semiconductor manufacturers can drive innovation, improve product quality, and meet the evolving demands of the semiconductor industry. As technology continues to advance, silicon nitride substrates will remain a key component in shaping the future of semiconductor manufacturing and driving progress in electronic devices and systems.