With the rapid development of power electronics technology, silicon carbide (SiC) power devices with their excellent high temperature stability, high energy density and low loss characteristics have shown great application potential in new energy vehicles, smart grids and efficient energy conversion fields. However, to fully exploit the performance advantages of SiC devices, it is crucial to select the right packaging substrate. Among the many ceramic substrate types, the active metal brazed (AMB) silicon nitride (Si3N4) substrate has gradually become the preferred solution for the packaging of SiC power devices with its unique advantages. The purpose of this paper is to explore why AMB ceramic substrates, especially Si3N4-AMB substrates, stand out and meet the packaging needs of SiC power devices for high temperature, high power, high heat dissipation and high reliability.

As the core component of power device package, the performance of ceramic substrate directly affects the overall performance of the device. Traditionally, alumina (Al2O3) substrates and aluminum nitride (AlN) substrates have been metallized by the direct copper coating (DBC) process, and while it is widely used, the inherent defects of the DBC process limit its application under extreme conditions. Specifically, due to the mismatch between the thermal expansion coefficient between copper and ceramic at high temperatures, the copper layer is easily peeled off, affecting the stability and reliability of the package structure.

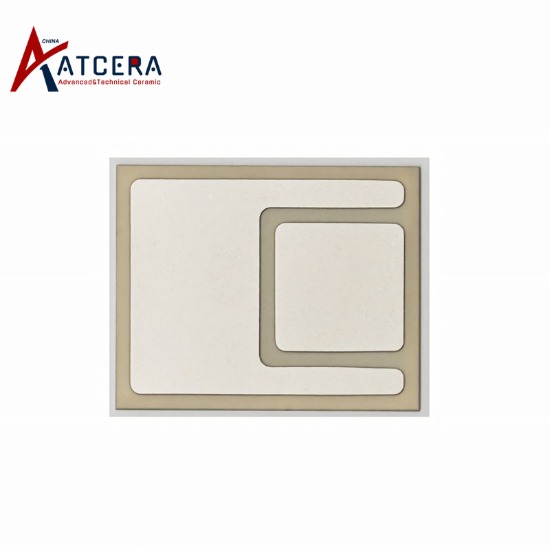

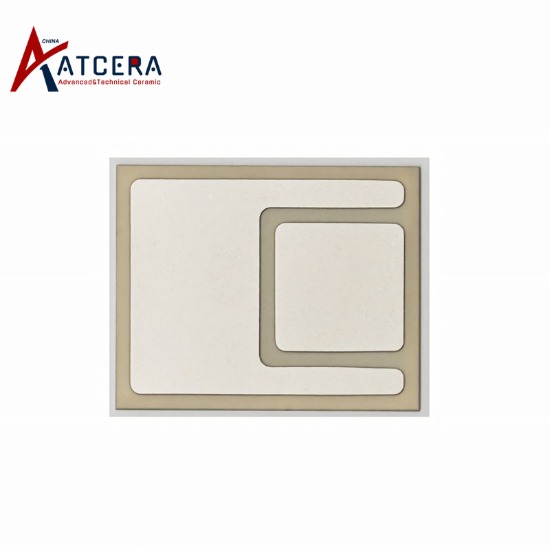

In contrast, active metal brazing (AMB) technology achieves a stronger chemical bond between copper and ceramics by introducing an active filler metal, significantly increasing the bonding strength of the interface. This technology not only overcomes the problem of peeling the DBC substrate at high temperatures, but also allows the use of ceramic materials with higher thermal conductivity and better mechanical properties, such as silicon nitride (Si3N4). Si3N4 ceramics are ideal for the AMB process due to their high hardness, high fracture toughness, good thermal stability and excellent thermal conductivity.

The SI3N4-AMB substrate combines the excellent properties of Si3N4 ceramics with the high strength of the AMB process, demonstrating excellent reliability under high temperature service conditions. First of all, its high thermal conductivity ensures effective heat dissipation of the device, reduces the operating temperature, and extends the life of the device. Secondly, the excellent mechanical properties of Si3N4 improve the bending strength and impact resistance of the substrate, enhancing the robustness of the package. Finally, the tight welded structure formed by the AMB process can effectively resist the interface failure caused by thermal stress at high temperature, and ensure the long-term stability of the package structure.

In summary, the rapid development of SiC power devices has put forward higher requirements for packaging substrates, and active metal brazed (AMB) silicon nitride (Si3N4) substrates are perfectly suited to the needs of SiC device packaging with their high strength bonding, high thermal conductivity, excellent mechanical properties, and excellent reliability at high temperatures. Si3N4-AMB substrate not only solves the interface stripping problem of traditional DBC substrate at high temperatures, but also provides a more stable and efficient heat dissipation channel for SiC devices, which is the key to promote SiC power devices to higher power density, higher operating temperature and a wider range of applications. Therefore, AMB ceramic substrates, especially Si3N4-AMB substrates, have undoubtedly become the preferred solution for SiC power device packaging, laying a solid foundation for the continuous progress of power electronics technology.