After entering the intelligent information age, semiconductor devices have quickly occupied our lives. Because the heat generated by the workpiece is a key factor causing the failure of semiconductor devices, in order to avoid many troubles caused by device failure and ensure its long-term effective and safe operation, it is necessary to be equipped with an efficient heat dissipation system.

At present, in the work of the industry for "heat dissipation", the replacement of the new power ceramic substrate is a very important part. Excellent high temperature resistance, corrosion resistance, high thermal conductivity, high mechanical strength, thermal expansion coefficient matched with the chip and not easy to deteriorate characteristics make the ceramic substrate more advantageous than metal, plastic and other materials, suitable for products with high heat and harsh outdoor environment, so it is more and more widely accepted by the public.

The ceramic substrate plays the following roles in semiconductor integrated circuits: providing mechanical support and environmental protection for chips and electronic components; Provides heat dissipation channels to avoid excessive local temperature, which improves device reliability. At present, the ceramic substrate materials that can meet these requirements are mainly alumina, aluminum nitride, beryllium oxide, silicon nitride and so on.

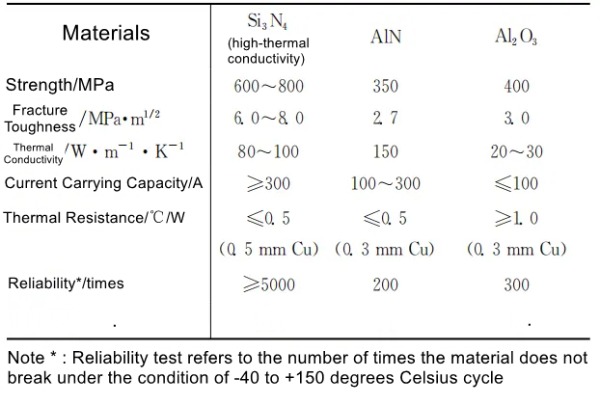

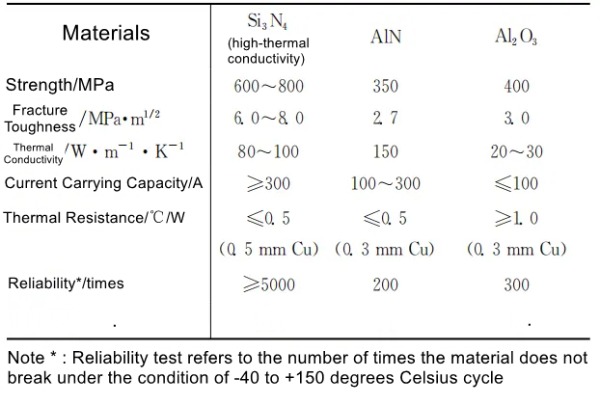

Among them, the advantage of silicon nitride ceramics is that it is a special ceramic with excellent comprehensive performance, with high strength, high hardness, high resistivity, good thermal shock resistance, low dielectric loss and low expansion coefficient, etc., all aspects of the performance is more balanced, is the best comprehensive performance of structural ceramic materials. And power electronic devices in high-speed rail, electric vehicles and other fields often face bumps, vibrations and other complex mechanical environment, so the excellent mechanical properties of silicon nitride ceramics precisely make it in the above fields have a strong competitiveness.

As for thermal properties, Lightfoot and Haggerty have proposed that the theoretical thermal conductivity of silicon nitride based on the structure of Si3N4 is between 200 and 300W/(m·K), so it is reasonable to say that silicon nitride has great potential in heat dissipation. However, the ideal is full, the reality is bone feeling, silicon nitride compared with other ceramic materials, the entry threshold is high, not only the technical difficulty is large, but also the processing cost is high, the current commercial silicon nitride substrate thermal conductivity is basically between 85-95W/m·K, higher thermal conductivity substrate (> 150W/m·K) is still in the laboratory stage.

In summary, with the in-depth development of the intelligent information age, the wide application of semiconductor devices has put forward higher requirements for heat dissipation technology. With its excellent mechanical support, environmental protection, heat dissipation performance and comprehensive performance, silicon nitride ceramics show great potential and competitiveness in the field of semiconductor devices, especially in complex mechanical environments such as high-speed rail and electric vehicles, and its advantages are more significant. However, the commercialization of silicon nitride ceramics is not a smooth road, and the technical difficulty and high processing cost have become the bottleneck restricting its large-scale application. Nevertheless, researchers are making unremitting efforts to break through technical difficulties and improve the thermal conductivity of silicon nitride ceramics, in order to achieve higher performance heat dissipation solutions in the future. We have reason to believe that with the continuous progress of technology and the gradual reduction of cost, silicon nitride ceramics will certainly shine in the field of semiconductor device heat dissipation and contribute an important force to the development of the intelligent information age.