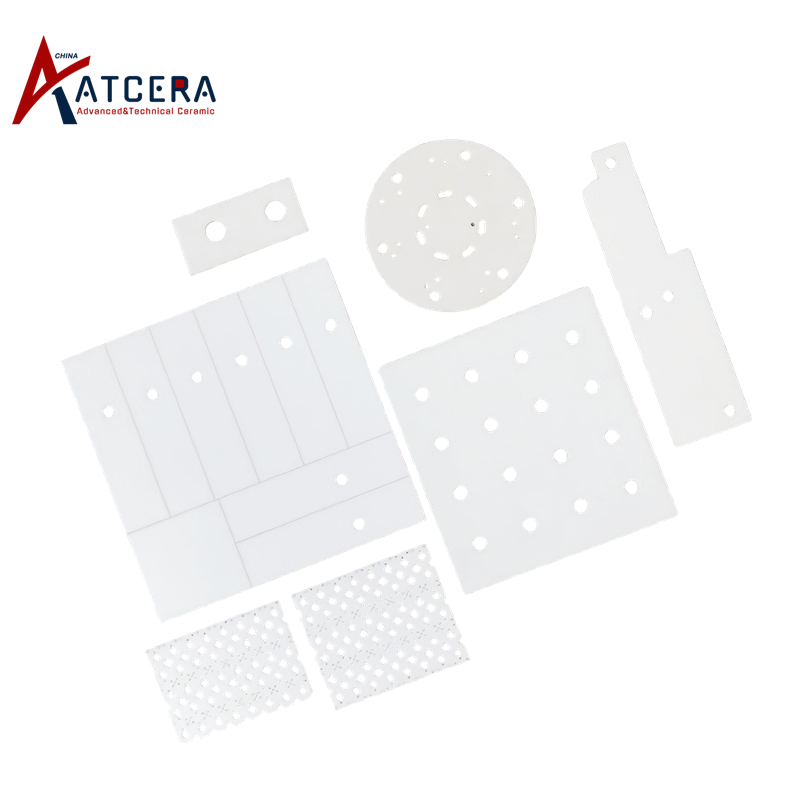

Applications of Alumina Substrate

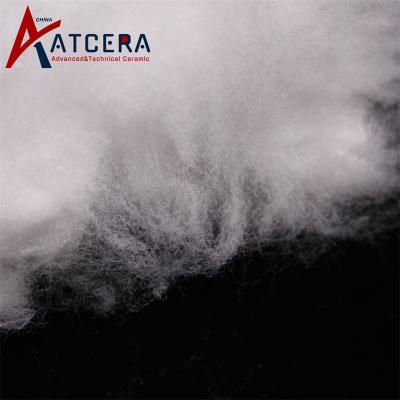

Alumina substrates and plates are widely used in thick and thin film integrated circuits, LED lighting, IGBT power modules, DBC coppers, thermal printers, ozone generators, semiconductor coolers, crystal oscillators, high voltage resistors, automotive and power tools and other power electronics and optoelectronic communication fields,etc.

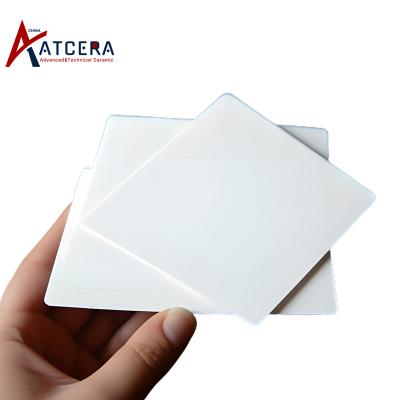

1. Electronic Industry

Alumina substrate has high insulation performance and excellent high temperature resistance, can meet the high reliability and high performance requirements of electronic components, mainly used in the manufacture of electronic components, such as electronic capacitors, resistors, magnetic components and so on. In addition, it can also be used to manufacture the medium layer of high-speed communication equipment to ensure the stable transmission of high-frequency signals.

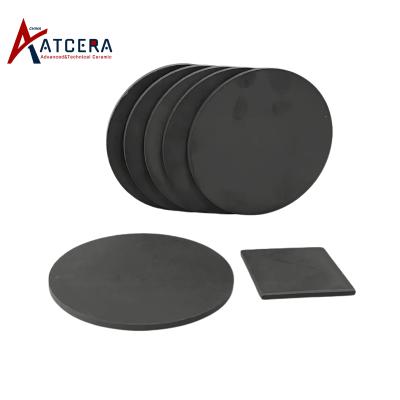

2. Photoelectric Industry

Al2O3 substrates can provide good thermal performance and mechanical strength, and are widely used in the photoelectric industry, especially in the manufacture of high-power leds, ensuring the stability and life of LED components. In addition, it can also be used to manufacture support materials for solar panels to enhance their mechanical strength and chemical resistance.

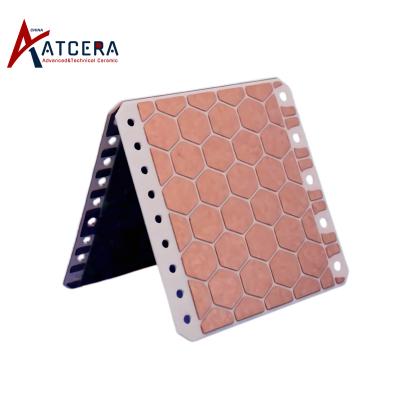

3. Electrical Industry

Alumina ceramic substrate has excellent insulation performance and good heat dissipation, and can be used to manufacture various high-power electrical components, such as power modules, heating modules, etc., effectively ensuring the service life and reliability of electrical equipment.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.