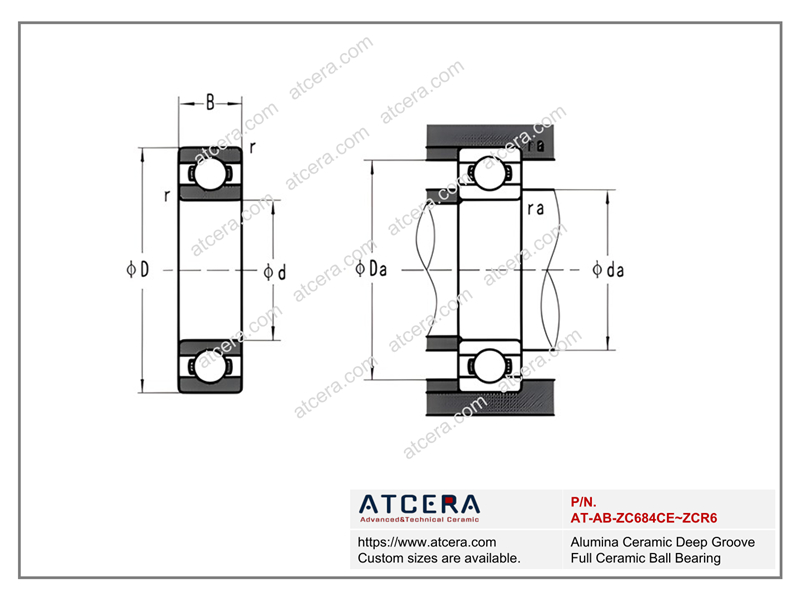

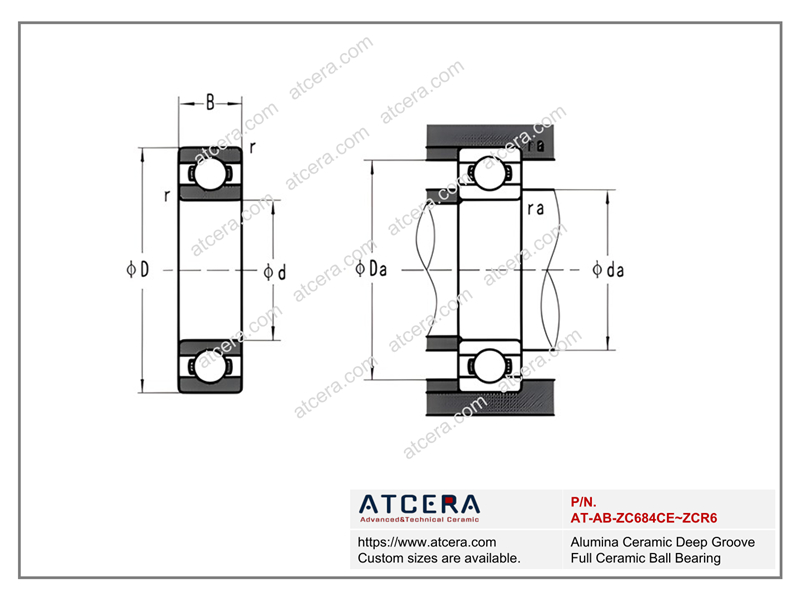

Size Chart of Alumina Ceramic Deep Groove Full Ceramic Ball Bearing

We are committed to delivering high-quality alumina ceramic bearings tailored to your exact specifications. Our dedicated team ensures meticulous adherence to your instructions, striving to exceed customer expectations. Additionally, we offer the flexibility of custom sizes to accommodate your unique requirements.

Please provide the requirements listed below if customized design needed:

1. Use environment, working temperature, design rotation speed, load and other parameters;

2. Size and tolerance requirements of outer diameter, inner diameter and height;

3. Drawings and specifications requirements.

The tolerance of inner diameter, outer diameter and thickness can be controlled within ±0.003mm, for higher precision please contact ATCERA.

| Alumina Ceramic Deep Groove Full Ceramic Ball Bearing |

| Item NO. |

d - Inner Diameter

(mm) |

D - Outer Diameter

(mm) |

B - Height

(mm) |

r

(Minimum) |

Installation Size (mm) |

da

(Minimum) |

da

(Maximum) |

Da

(Maximum) |

ra

(Maximum) |

| AT-AB-ZC684CE |

4 |

9 |

2.5 |

0.1 |

4.8 |

/ |

8.2 |

0.1 |

| AT-AB-ZC694CE |

4 |

11 |

4 |

0.15 |

5.2 |

/ |

9.8 |

0.15 |

| AT-AB-ZC604CE |

4 |

12 |

4 |

0.2 |

5.6 |

/ |

10.4 |

0.2 |

| AT-AB-ZC624CE |

4 |

13 |

5 |

0.2 |

5.6 |

/ |

11.4 |

0.2 |

| AT-AB-ZC634CE |

4 |

16 |

5 |

0.3 |

6 |

/ |

14 |

0.3 |

| AT-AB-ZC685CE |

5 |

11 |

3 |

0.15 |

6.2 |

/ |

9.8 |

0.15 |

| AT-AB-ZC695CE |

5 |

13 |

4 |

0.2 |

6.6 |

/ |

11.4 |

0.2 |

| AT-AB-ZC605CE |

5 |

14 |

5 |

0.2 |

6.6 |

/ |

12.4 |

0.2 |

| AT-AB-ZC625CE |

5 |

16 |

5 |

0.3 |

7 |

/ |

14 |

0.3 |

| AT-AB-ZC635CE |

5 |

19 |

6 |

0.3 |

7 |

/ |

17 |

0.3 |

| AT-AB-ZC686CE |

6 |

13 |

3.5 |

0.15 |

7.2 |

/ |

11.8 |

0.15 |

| AT-AB-ZC696CE |

7 |

15 |

5 |

0.2 |

7.6 |

/ |

13.4 |

0.2 |

| AT-AB-ZC606CE |

8 |

17 |

6 |

0.3 |

8 |

/ |

15 |

0.3 |

| AT-AB-ZC626CE |

9 |

19 |

6 |

0.3 |

8 |

/ |

17 |

0.3 |

| AT-AB-ZC636CE |

10 |

22 |

7 |

0.3 |

8 |

/ |

20 |

0.3 |

| AT-AB-ZC687CE |

7 |

14 |

3.5 |

0.15 |

8.2 |

/ |

12.8 |

0.15 |

| AT-AB-ZC697CE |

7 |

17 |

5 |

0.3 |

9 |

/ |

15 |

0.3 |

| AT-AB-ZC607CE |

7 |

19 |

6 |

0.3 |

9 |

/ |

17 |

0.3 |

| AT-AB-ZC627CE |

7 |

22 |

7 |

0.3 |

9 |

/ |

20 |

0.3 |

| AT-AB-ZC637CE |

7 |

26 |

9 |

0.3 |

9 |

/ |

24 |

0.3 |

| AT-AB-ZC688CE |

8 |

16 |

4 |

0.2 |

9.6 |

/ |

14.4 |

0.2 |

| AT-AB-ZC698CE |

8 |

19 |

6 |

0.3 |

10 |

/ |

17 |

0.3 |

| AT-AB-ZC608CE |

8 |

22 |

7 |

0.3 |

10 |

/ |

20 |

0.3 |

| AT-AB-ZC628CE |

8 |

24 |

8 |

0.3 |

10 |

/ |

22 |

0.3 |

| AT-AB-ZC638CE |

8 |

28 |

9 |

0.3 |

10 |

/ |

26 |

0.3 |

| AT-AB-ZC689CE |

9 |

17 |

4 |

0.2 |

10.6 |

/ |

15.4 |

0.2 |

| AT-AB-ZC699CE |

9 |

20 |

6 |

0.3 |

11 |

/ |

18 |

0.3 |

| AT-AB-ZC609CE |

9 |

24 |

7 |

0.3 |

11 |

/ |

22 |

0.3 |

| AT-AB-ZC629CE |

9 |

26 |

8 |

0.3 |

11 |

/ |

24 |

0.3 |

| AT-AB-ZC639CE |

9 |

30 |

10 |

0.6 |

13 |

/ |

26 |

0.6 |

| AT-AB-ZC6800CE |

10 |

19 |

5 |

0.3 |

12 |

12 |

17 |

0.3 |

| AT-AB-ZC6900CE |

10 |

22 |

6 |

0.3 |

12 |

12.5 |

20 |

0.3 |

| AT-AB-ZC6000CE |

10 |

26 |

8 |

0.3 |

12 |

13 |

24 |

0.3 |

| AT-AB-ZC6200CE |

10 |

30 |

9 |

0.6 |

14 |

16 |

26 |

0.6 |

| AT-AB-ZC6300CE |

10 |

35 |

11 |

0.6 |

14 |

16.5 |

31 |

0.6 |

| AT-AB-ZC6801CE |

12 |

21 |

5 |

0.3 |

14 |

14 |

19 |

0.3 |

| AT-AB-ZC6901CE |

12 |

24 |

6 |

0.3 |

14 |

14.5 |

22 |

0.3 |

| AT-AB-ZC16001CE |

12 |

28 |

7 |

0.3 |

14 |

/ |

26 |

0.3 |

| AT-AB-ZC6001CE |

12 |

28 |

8 |

0.3 |

14 |

15.5 |

26 |

0.3 |

| AT-AB-ZC6201CE |

12 |

32 |

10 |

0.6 |

16 |

17 |

28 |

0.6 |

| AT-AB-ZC6301CE |

12 |

37 |

12 |

1 |

17 |

18 |

32 |

1 |

| AT-AB-ZC6802CE |

15 |

24 |

5 |

0.3 |

17 |

17 |

22 |

0.3 |

| AT-AB-ZC6902CE |

15 |

28 |

7 |

0.3 |

17 |

17 |

26 |

0.3 |

| AT-AB-ZC16002CE |

15 |

32 |

8 |

0.3 |

17 |

/ |

30 |

0.3 |

| AT-AB-ZC6002CE |

15 |

32 |

9 |

0.3 |

17 |

19 |

30 |

0.3 |

| AT-AB-ZC6202CE |

15 |

35 |

11 |

0.6 |

19 |

20.5 |

31 |

0.3 |

| AT-AB-ZC6302CE |

15 |

42 |

13 |

1 |

20 |

22.5 |

37 |

1 |

| AT-AB-ZC6803CE |

17 |

26 |

5 |

0.3 |

19 |

19 |

24 |

0.3 |

| AT-AB-ZC6903CE |

17 |

30 |

7 |

0.3 |

19 |

19.5 |

28 |

0.3 |

| AT-AB-ZC16003CE |

17 |

35 |

8 |

0.3 |

19 |

/ |

33 |

0.3 |

| AT-AB-ZC6003CE |

17 |

35 |

10 |

0.3 |

19 |

21.5 |

33 |

0.3 |

| AT-AB-ZC6203CE |

17 |

40 |

12 |

0.6 |

21 |

23.5 |

36 |

0.6 |

| AT-AB-ZC6303CE |

17 |

47 |

14 |

1 |

22 |

25.5 |

42 |

1 |

| AT-AB-ZC6403CE |

17 |

62 |

17 |

1.1 |

23.5 |

/ |

55.5 |

1 |

| AT-AB-ZC6804CE |

20 |

32 |

7 |

0.3 |

22 |

22.5 |

30 |

0.3 |

| AT-AB-ZC6904CE |

20 |

37 |

9 |

0.3 |

22 |

24 |

35 |

0.3 |

| AT-AB-ZC16004CE |

20 |

42 |

8 |

0.3 |

22 |

/ |

40 |

0.3 |

| AT-AB-ZC6004CE |

20 |

42 |

12 |

0.6 |

24 |

25.5 |

38 |

0.6 |

| AT-AB-ZC6204CE |

20 |

47 |

14 |

1 |

25 |

26.5 |

42 |

1 |

| AT-AB-ZC6304CE |

20 |

52 |

15 |

1.1 |

26.5 |

28 |

45.5 |

1 |

| AT-AB-ZC6404CE |

20 |

72 |

19 |

1.1 |

26.5 |

/ |

65.5 |

1 |

| AT-AB-ZC6805CE |

25 |

37 |

7 |

0.3 |

27 |

27 |

35 |

0.3 |

| AT-AB-ZC6905CE |

25 |

42 |

9 |

0.3 |

27 |

28.5 |

40 |

0.3 |

| AT-AB-ZC16005CE |

25 |

47 |

8 |

0.3 |

27 |

/ |

45 |

0.3 |

| AT-AB-ZC6005CE |

25 |

47 |

12 |

0.6 |

29 |

30 |

43 |

0.6 |

| AT-AB-ZC6205CE |

25 |

52 |

15 |

1 |

30 |

32 |

47 |

1 |

| AT-AB-ZC6305CE |

25 |

62 |

17 |

1.1 |

31.5 |

36 |

55.5 |

1 |

| AT-AB-ZC6405CE |

25 |

80 |

21 |

1.5 |

33 |

/ |

72 |

1.5 |

| AT-AB-ZC6806CE |

30 |

42 |

7 |

0.3 |

32 |

32 |

50 |

1 |

| AT-AB-ZC6906CE |

30 |

47 |

9 |

0.3 |

32 |

34 |

57 |

1 |

| AT-AB-ZC16006CE |

30 |

55 |

9 |

0.3 |

32 |

42.5 |

65.5 |

1 |

| AT-AB-ZC6006CE |

30 |

55 |

13 |

1 |

35 |

36.5 |

53 |

1 |

| AT-AB-ZC6206CE |

30 |

62 |

16 |

1 |

35 |

38.5 |

60 |

1 |

| AT-AB-ZC6306CE |

30 |

72 |

19 |

1.1 |

36.5 |

42.5 |

68.5 |

1 |

| AT-AB-ZC6406CE |

30 |

90 |

23 |

1.5 |

54 |

/ |

82 |

2 |

| AT-AB-ZC6807CE |

35 |

47 |

7 |

0.3 |

37 |

37 |

45 |

0.3 |

| AT-AB-ZC6907CE |

35 |

55 |

10 |

0.6 |

39 |

39 |

51 |

0.6 |

| AT-AB-ZC16007CE |

35 |

62 |

9 |

0.3 |

37 |

/ |

60 |

0.3 |

| AT-AB-ZC6007CE |

35 |

62 |

14 |

1 |

40 |

41.5 |

57 |

1 |

| AT-AB-ZC6207CE |

35 |

72 |

17 |

1.1 |

41.5 |

44.5 |

65.5 |

1 |

| AT-AB-ZC6307CE |

35 |

80 |

21 |

1.5 |

43 |

47 |

72 |

1.5 |

| AT-AB-ZC6407CE |

35 |

100 |

25 |

1.5 |

43 |

/ |

92 |

1.5 |

| AT-AB-ZC6808CE |

40 |

52 |

7 |

0.3 |

42 |

42 |

50 |

0.3 |

| AT-AB-ZC6908CE |

40 |

62 |

12 |

0.6 |

44 |

46 |

58 |

0.6 |

| AT-AB-ZC16008CE |

40 |

68 |

9 |

0.3 |

42 |

/ |

66 |

0.3 |

| AT-AB-ZC6008CE |

40 |

68 |

15 |

1 |

45 |

47.5 |

63 |

1 |

| AT-AB-ZC6208CE |

40 |

80 |

18 |

1.1 |

46.5 |

50.5 |

73.5 |

1 |

| AT-AB-ZC6308CE |

40 |

90 |

23 |

1.5 |

48 |

53 |

80 |

1.5 |

| AT-AB-ZC6408CE |

40 |

110 |

27 |

2 |

49 |

/ |

101 |

2 |

| AT-AB-ZC6809CE |

45 |

58 |

7 |

0.3 |

47 |

47.5 |

56 |

0.3 |

| AT-AB-ZC6909CE |

45 |

68 |

12 |

0.6 |

49 |

50 |

64 |

0.6 |

| AT-AB-ZC16009CE |

45 |

75 |

10 |

0.6 |

49 |

/ |

71 |

0.6 |

| AT-AB-ZC6009CE |

45 |

75 |

16 |

1 |

50 |

53.5 |

70 |

1 |

| AT-AB-ZC6209CE |

45 |

85 |

19 |

1.1 |

51.5 |

55.5 |

78.5 |

1 |

| AT-AB-ZC6309CE |

45 |

100 |

25 |

1.5 |

53 |

61.5 |

92 |

1.5 |

| AT-AB-ZC6409CE |

45 |

120 |

29 |

2 |

54 |

/ |

111 |

2 |

| AT-AB-ZC6810CE |

50 |

65 |

7 |

0.3 |

52 |

52.5 |

63 |

0.3 |

| AT-AB-ZC6910CE |

50 |

72 |

12 |

0.6 |

54 |

55 |

68 |

0.6 |

| AT-AB-ZC16010CE |

50 |

80 |

10 |

0.6 |

54 |

/ |

76 |

0.6 |

| AT-AB-ZC6010CE |

50 |

80 |

16 |

1 |

55 |

58.5 |

75 |

1 |

| AT-AB-ZC6210CE |

50 |

90 |

20 |

1.1 |

56.5 |

60 |

83.2 |

1 |

| AT-AB-ZC6310CE |

50 |

110 |

27 |

2 |

59 |

68 |

101 |

2 |

| AT-AB-ZC6410CE |

50 |

130 |

31 |

2.1 |

61 |

/ |

119 |

2 |

| AT-AB-ZC6811CE |

55 |

72 |

9 |

0.3 |

57 |

59 |

70 |

0.3 |

| AT-AB-ZC6911CE |

55 |

80 |

13 |

1 |

60 |

61.5 |

75 |

1 |

| AT-AB-ZC16011CE |

55 |

90 |

11 |

0.6 |

59 |

/ |

86 |

0.6 |

| AT-AB-ZC6011CE |

55 |

90 |

18 |

1.1 |

61.5 |

64 |

83.5 |

1 |

| AT-AB-ZC6211CE |

55 |

100 |

21 |

1.5 |

63 |

66.5 |

92 |

1.5 |

| AT-AB-ZC6311CE |

55 |

120 |

29 |

2 |

64 |

72.5 |

111 |

2 |

| AT-AB-ZC6411CE |

55 |

140 |

33 |

2.1 |

66 |

/ |

129 |

2 |

| AT-AB-ZC6812CE |

60 |

78 |

10 |

0.3 |

62 |

64 |

76 |

0.3 |

| AT-AB-ZC6912CE |

60 |

85 |

13 |

1 |

65 |

66 |

80 |

1 |

| AT-AB-ZC16012CE |

60 |

95 |

11 |

0.6 |

64 |

/ |

91 |

0.6 |

| AT-AB-ZC6012CE |

60 |

95 |

18 |

1.1 |

66.5 |

69 |

88.5 |

1 |

| AT-AB-ZC6212CE |

60 |

110 |

22 |

1.5 |

68 |

74.5 |

102 |

1.5 |

| AT-AB-ZC6312CE |

60 |

130 |

31 |

2.1 |

71 |

79 |

119 |

2 |

| AT-AB-ZC6412CE |

60 |

150 |

35 |

2.1 |

71 |

|

139 |

2 |

| AT-AB-ZC6813CE |

65 |

85 |

10 |

0.6 |

69 |

69 |

81 |

0.6 |

| AT-AB-ZC6913CE |

65 |

90 |

13 |

1 |

70 |

71.5 |

85 |

1 |

| AT-AB-ZC16013CE |

65 |

100 |

11 |

0.6 |

69 |

/ |

96 |

0.6 |

| AT-AB-ZC6013CE |

65 |

100 |

18 |

1.1 |

71.5 |

73 |

93.5 |

1 |

| AT-AB-ZC6213CE |

65 |

120 |

23 |

1.5 |

73 |

80 |

112 |

1.5 |

| AT-AB-ZC6313CE |

65 |

140 |

33 |

2.1 |

76 |

85.5 |

129 |

2 |

| AT-AB-ZC6814CE |

70 |

90 |

10 |

0.6 |

74 |

74.5 |

86 |

0.6 |

| AT-AB-ZC6914CE |

70 |

100 |

16 |

1 |

75 |

77.5 |

95 |

1 |

| AT-AB-ZC16014CE |

70 |

110 |

13 |

0.6 |

74 |

/ |

106 |

0.6 |

| AT-AB-ZC6014CE |

70 |

110 |

20 |

1.1 |

76.5 |

80.5 |

103.5 |

1 |

| AT-AB-ZC6214CE |

70 |

125 |

24 |

1.5 |

78 |

84 |

117 |

1.5 |

| AT-AB-ZC6314CE |

70 |

150 |

35 |

2.1 |

81 |

92 |

139 |

2 |

| AT-AB-ZC6815CE |

75 |

95 |

10 |

0.6 |

79 |

79.5 |

91 |

0.6 |

| AT-AB-ZC6915CE |

75 |

105 |

16 |

1 |

80 |

82 |

100 |

1 |

| AT-AB-ZC16015CE |

75 |

115 |

13 |

0.6 |

79 |

/ |

111 |

0.6 |

| AT-AB-ZC6015CE |

75 |

115 |

20 |

1.1 |

81.5 |

85.5 |

108.5 |

1 |

| AT-AB-ZC6215CE |

75 |

130 |

25 |

1.5 |

83 |

90 |

122 |

1.5 |

| AT-AB-ZC6816CE |

80 |

100 |

10 |

0.6 |

84 |

84.5 |

96 |

0.6 |

| AT-AB-ZC6916CE |

80 |

110 |

16 |

1 |

85 |

87.5 |

105 |

1 |

| AT-AB-ZC16016CE |

80 |

125 |

14 |

0.6 |

84 |

/ |

121 |

0.6 |

| AT-AB-ZC6016CE |

80 |

125 |

22 |

1.1 |

86.5 |

91 |

118.5 |

1 |

| AT-AB-ZC6216CE |

80 |

140 |

26 |

2 |

89 |

95.5 |

131 |

2 |

| AT-AB-ZC6817CE |

85 |

110 |

13 |

1 |

90 |

90.5 |

105 |

1 |

| AT-AB-ZC6917CE |

85 |

120 |

18 |

1.1 |

91.5 |

94.5 |

113.5 |

1 |

| AT-AB-ZC16017CE |

85 |

130 |

14 |

0.6 |

89 |

/ |

126 |

0.6 |

| AT-AB-ZC6017CE |

85 |

130 |

22 |

1.1 |

91.5 |

96 |

123.5 |

1 |

| AT-AB-ZC6217CE |

85 |

150 |

28 |

2 |

94 |

102 |

141 |

2 |

| AT-AB-ZC6818CE |

90 |

115 |

13 |

1 |

95 |

95.5 |

110 |

1 |

| AT-AB-ZC6918CE |

90 |

125 |

18 |

1.1 |

96.5 |

98.5 |

118.5 |

1 |

| AT-AB-ZC16018CE |

90 |

140 |

16 |

1 |

95 |

/ |

135 |

1 |

| AT-AB-ZC6018CE |

90 |

140 |

24 |

1.5 |

98 |

103 |

132 |

1.5 |

| AT-AB-ZC6819CE |

95 |

120 |

13 |

1 |

100 |

102 |

115 |

1 |

| AT-AB-ZC6919CE |

95 |

130 |

18 |

1.1 |

101.5 |

104 |

123.5 |

1 |

| AT-AB-ZC16019CE |

95 |

145 |

16 |

1 |

100 |

/ |

140 |

1 |

| AT-AB-ZC6019CE |

95 |

145 |

24 |

1.5 |

103 |

109 |

137 |

1.5 |

| AT-AB-ZC6820CE |

100 |

125 |

13 |

1 |

105 |

106 |

120 |

1 |

| AT-AB-ZC6920CE |

100 |

140 |

20 |

1.1 |

106.5 |

111 |

133.5 |

1 |

| AT-AB-ZC16020CE |

100 |

150 |

16 |

1 |

105 |

/ |

145 |

1 |

| AT-AB-ZC6020CE |

100 |

150 |

24 |

1.5 |

108 |

113 |

142 |

1.5 |

| AT-AB-ZC6821CE |

105 |

130 |

13 |

1 |

110 |

111 |

125 |

1 |

| AT-AB-ZC6921CE |

105 |

145 |

20 |

1.1 |

111.5 |

116 |

138.5 |

1 |

| AT-AB-ZC6822CE |

110 |

140 |

16 |

1 |

115 |

117 |

135 |

1 |

| AT-AB-ZC6922CE |

|

150 |

20 |

1.1 |

116.5 |

121 |

143.5 |

1 |

| AT-AB-ZC6824CE |

120 |

150 |

16 |

1 |

125 |

127 |

145 |

1 |

| AT-AB-ZC6924 |

120 |

165 |

22 |

1.1 |

|

|

|

|

| AT-AB-ZC16024 |

120 |

180 |

19 |

1 |

|

|

|

|

| AT-AB-ZC6024 |

120 |

180 |

28 |

2 |

|

|

|

|

| AT-AB-ZC6224 |

120 |

215 |

40 |

2.1 |

|

|

|

|

| AT-AB-ZC6324 |

120 |

260 |

55 |

3 |

|

|

|

|

| AT-AB-ZC6826 |

130 |

165 |

18 |

1.1 |

|

|

|

|

| AT-AB-ZC6926 |

130 |

180 |

24 |

1.5 |

|

|

|

|

| AT-AB-ZC16026 |

130 |

200 |

22 |

1.1 |

|

|

|

|

| AT-AB-ZC6026 |

130 |

200 |

33 |

2 |

|

|

|

|

| AT-AB-ZC6226 |

130 |

230 |

40 |

3 |

|

|

|

|

| AT-AB-ZC6326 |

130 |

280 |

58 |

4 |

|

|

|

|

| AT-AB-ZC6828 |

140 |

175 |

18 |

1.1 |

|

|

|

|

| AT-AB-ZC6928 |

140 |

190 |

24 |

1.5 |

|

|

|

|

| AT-AB-ZC16028 |

140 |

210 |

22 |

1.1 |

|

|

|

|

| AT-AB-ZC6028 |

140 |

210 |

33 |

2 |

|

|

|

|

| AT-AB-ZC6228 |

140 |

250 |

42 |

3 |

|

|

|

|

| AT-AB-ZC6328 |

140 |

300 |

62 |

4 |

|

|

|

|

| AT-AB-ZC6830 |

150 |

190 |

20 |

1.1 |

|

|

|

|

| AT-AB-ZC6930 |

150 |

210 |

28 |

2 |

|

|

|

|

| AT-AB-ZC16030 |

150 |

225 |

24 |

1.1 |

|

|

|

|

| AT-AB-ZC6030 |

150 |

225 |

35 |

2.1 |

|

|

|

|

| AT-AB-ZC6230 |

150 |

270 |

45 |

3 |

|

|

|

|

| AT-AB-ZC6330 |

150 |

320 |

65 |

4 |

|

|

|

|

| AT-AB-ZC60/22 |

22 |

44 |

12 |

0.6 |

|

|

|

|

| AT-AB-ZC62/22 |

22 |

50 |

14 |

1 |

|

|

|

|

| AT-AB-ZC63/22 |

22 |

56 |

16 |

1.1 |

|

|

|

|

| AT-AB-ZC60/28 |

28 |

52 |

12 |

0.6 |

|

|

|

|

| AT-AB-ZC62/28 |

28 |

58 |

16 |

1 |

|

|

|

|

| AT-AB-ZC63/28 |

28 |

68 |

18 |

1.1 |

|

|

|

|

| AT-AB-ZC60/32 |

33 |

58 |

13 |

1 |

|

|

|

|

| AT-AB-ZC62/32 |

33 |

65 |

17 |

1 |

|

|

|

|

| AT-AB-ZC63/32 |

33 |

75 |

20 |

1.1 |

|

|

|

|

| AT-AB-ZC603CE |

3 |

9 |

3 |

|

|

|

|

|

| AT-AB-ZC606CE |

6 |

17 |

6 |

|

|

|

|

|

| AT-AB-ZCMR117 |

7 |

11 |

3 |

|

|

|

|

|

| AT-AB-ZCMR128 |

8 |

12 |

3.5 |

|

|

|

|

|

| AT-AB-ZCMR85 |

5 |

8 |

2.5 |

|

|

|

|

|

| AT-AB-ZCMR63-1 |

3 |

6 |

2.5 |

|

|

|

|

|

| AT-AB-ZCMR85-1 |

5 |

8 |

2 |

|

|

|

|

|

| AT-AB-ZCMR148 |

8 |

14 |

4 |

|

|

|

|

|

| AT-AB-ZCMR84 |

4 |

8 |

2 |

|

|

|

|

|

| AT-AB-ZCMR126 |

6 |

12 |

4 |

|

|

|

|

|

| AT-AB-ZCMR74-1 |

4 |

7 |

2 |

|

|

|

|

|

| AT-AB-ZCMR84-1 |

4 |

8 |

3 |

|

|

|

|

|

| AT-AB-ZCMR74 |

4 |

7 |

2.5 |

|

|

|

|

|

| AT-AB-ZCMR148 |

8 |

14 |

3.5 |

|

|

|

|

|

| AT-AB-ZCMR63 |

3 |

6 |

2 |

|

|

|

|

|

| AT-AB-ZCMR103 |

3 |

10 |

4 |

|

|

|

|

|

| AT-AB-ZCMR104 |

4 |

10 |

4 |

|

|

|

|

|

| AT-AB-ZCMR105 |

5 |

10 |

3 |

|

|

|

|

|

| AT-AB-ZCMR105-1 |

5 |

10 |

4 |

|

|

|

|

|

| AT-AB-ZCMR106 |

6 |

10 |

2.5 |

|

|

|

|

|

| AT-AB-ZCMR106-1 |

6 |

10 |

3 |

|

|

|

|

|

| AT-AB-ZCMR115 |

5 |

11 |

4 |

|

|

|

|

|

| AT-AB-ZCMR52 |

2 |

5 |

2.5 |

|

|

|

|

|

| AT-AB-ZCMR62 |

2 |

6 |

2.5 |

|

|

|

|

|

| AT-AB-ZCMR94 |

4 |

9 |

3 |

|

|

|

|

|

| AT-AB-ZCMR95 |

5 |

9 |

3 |

|

|

|

|

|

| AT-AB-ZCR188 |

6.35 |

12.7 |

4.763 |

|

|

|

|

|

| AT-AB-ZCR6 |

9.525 |

22.225 |

5.556 |

|

|

|

|

|

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.