FAQ

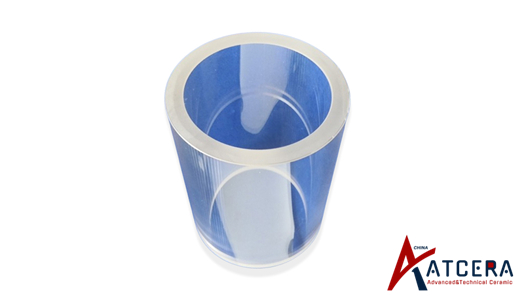

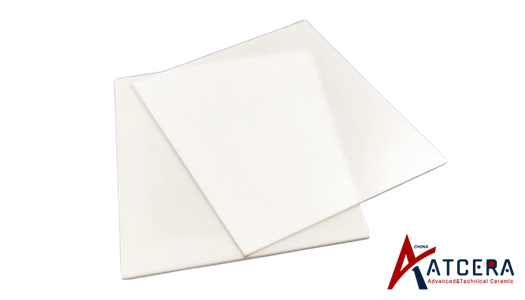

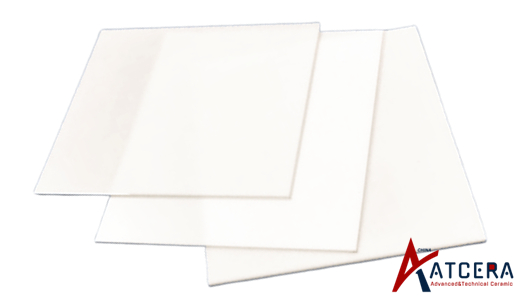

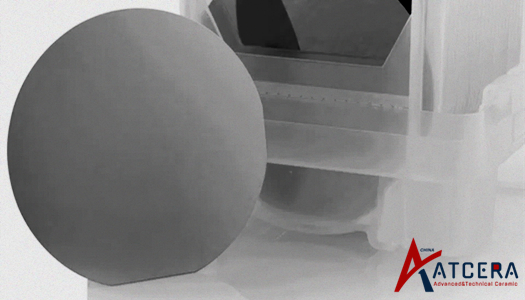

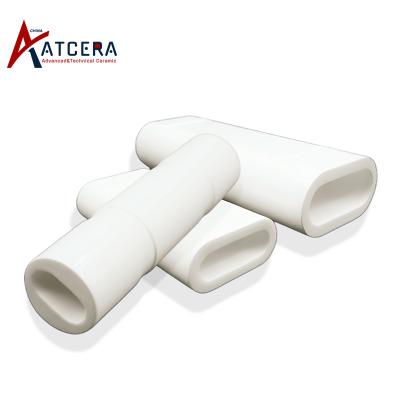

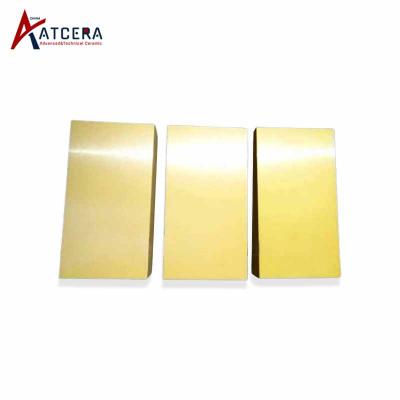

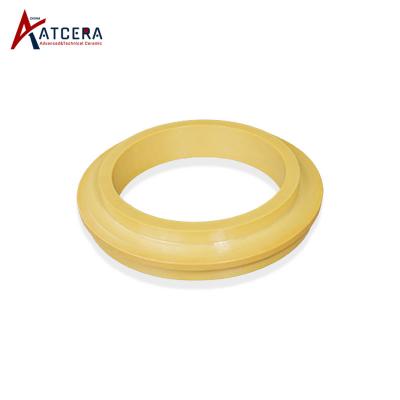

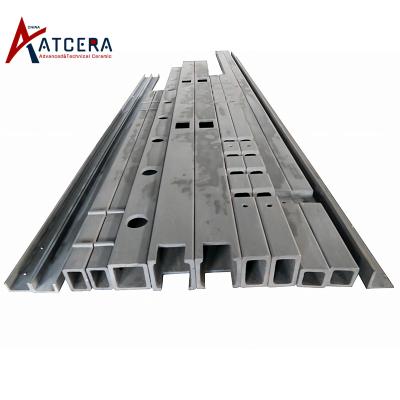

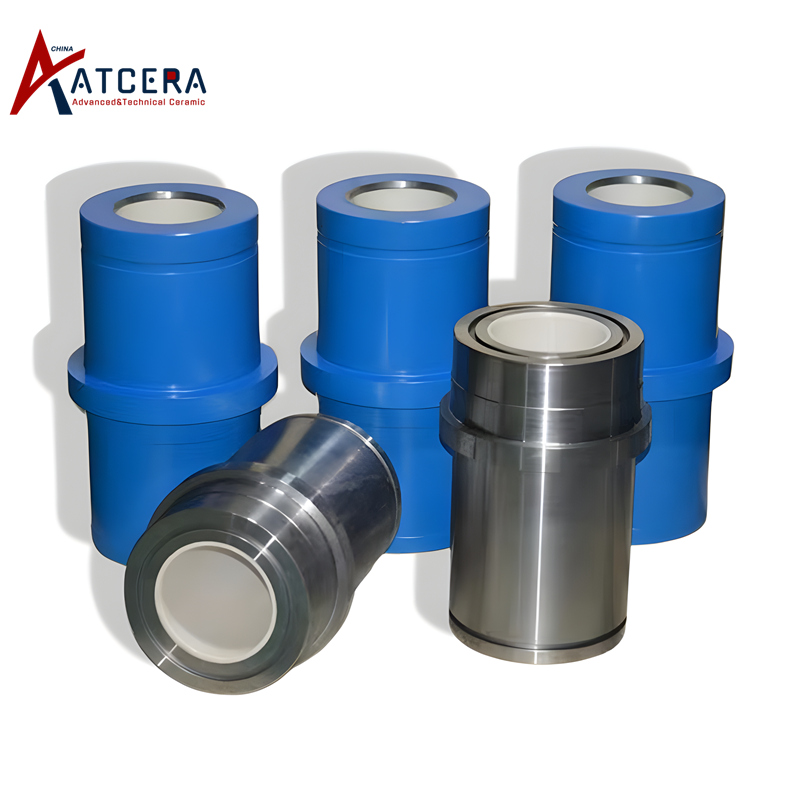

Although our primary focus is on advanced ceramic materials such as alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and quartz ceramics, we are always exploring new materials and technologies. If you have a specific material requirement, please contact us, and we will do our best to fulfill your needs or find suitable partners.

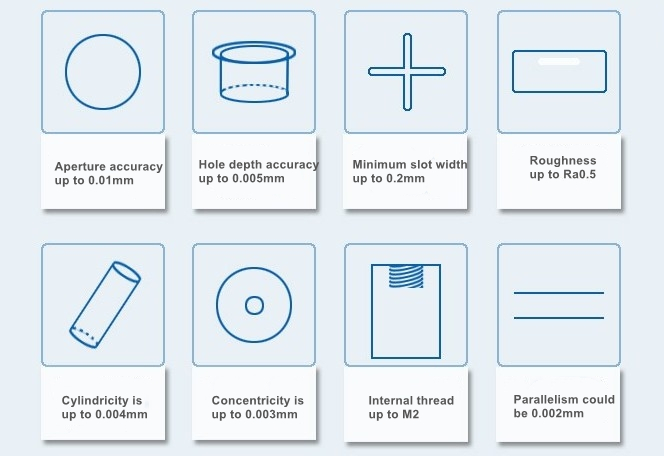

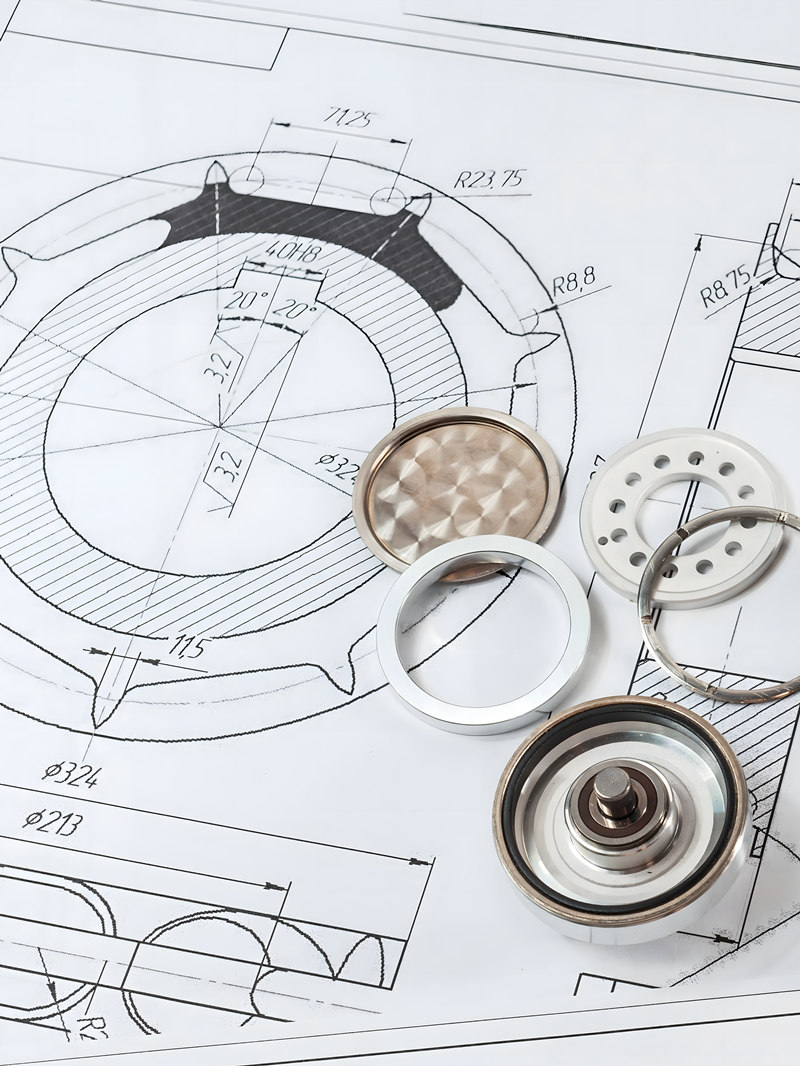

Absolutely. Our technical team possesses profound knowledge of ceramic materials and extensive experience in product design. We are happy to provide you with material selection advice and product design support to ensure optimal performance for your products.

We do not have a fixed minimum order value requirement. We always focus on meeting our customers' needs, and we strive to provide quality service and products regardless of the order size.

In addition to ceramic products, we also provide a range of additional services, including but not limited to: customized ceramic processing services based on your needs, using blanks or semi-finished blanks produced by yourself; if you are interested in outsourced ceramic packaging and metallization services, please contact us for further discussion. We are always committed to providing you with a one-stop solution to meet your various needs.

Yes, we do. No matter where you are located globally, we can ensure the safe and timely delivery of your order.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.