The chemical alumina family has a large number of different characteristics, and the preparation conditions are also different, such as α-alumina must be prepared by calcination at about 1300℃; Gamma-alumina is usually fired at a lower temperature of about 500 ° C; The doped modified alumina must introduce other elements (such as iron, chromium, lanthanum, etc.) to meet the application; High purity alumina, on the contrary, must be as far as possible to avoid the incorporation of external impurities... This makes the calcination process a very big challenge for the vehicle.

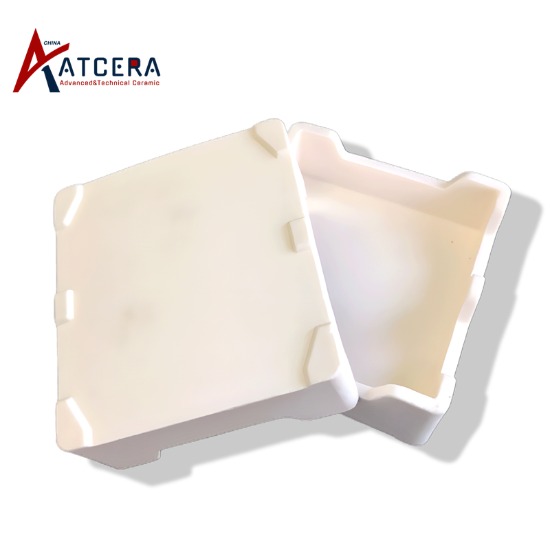

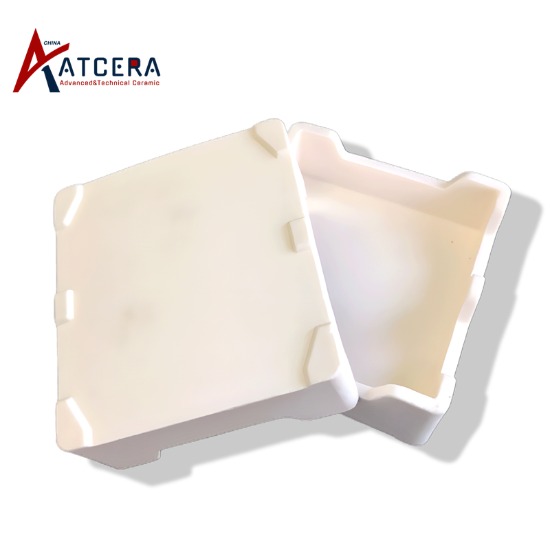

Alumina tray is usually made of various refractory materials, and is used in calcining operations to avoid direct contact with pyrotechnics, dust and slag falling on the kiln roof. In order to meet the efficient production of different varieties of alumina, customized crucible tray for different conditions also came into being.

High Temperature Alumina (Clay Crucible Tray)

High temperature alumina mainly refers to α-alumina, with excellent heat resistance and chemical stability, usually used to manufacture high strength, high hardness of ceramics, refractory materials, metal oxide composite materials and so on.

Clay, with its thick texture and stable structure, is an ideal raw material for making ceramics. Bauxite mainly contains alumina and silicon oxide, as auxiliary materials to strengthen the clay at the same time can also improve its toughness, smoothness, fastness, high temperature resistance, thermal stability and surface gloss. Made of high-quality clay, bauxite and other materials, after screening, iron removal, mixing, stirring, stale, forming, drying, firing and other processes made of clay crucible, very suitable for tunnel kiln, push plate kiln alumina calcining operations.

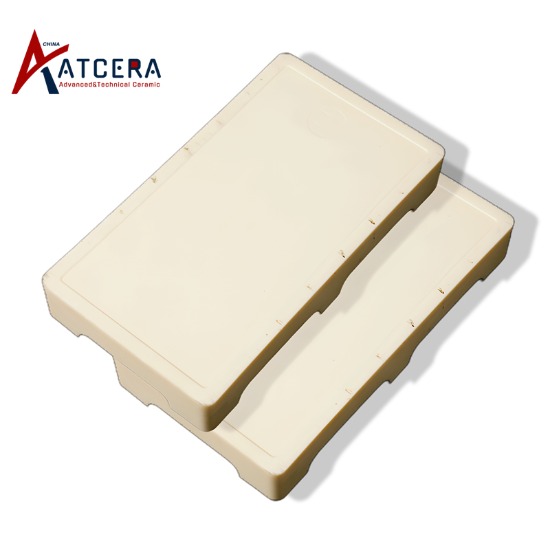

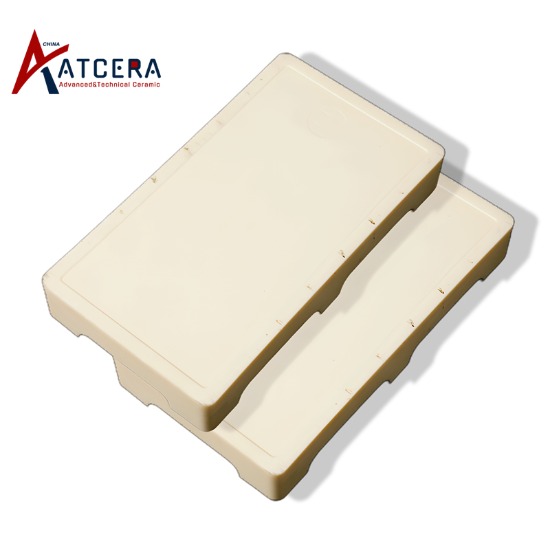

High Purity Alumina (Mullite Crucible Tray)

The market of high purity alumina covers many high cutting-edge applications such as electronic power, biomedicine, semiconductor, LED to military and aerospace.

The crystal structure of mullite is mainly composed of alumina and aluminum silicate arranged in a specific proportion, which has excellent corrosion resistance, chemical stability, heat preservation and fire resistance. At the same time, the melting point of mullite is nearly 1900℃, which can withstand the high temperature in the furnace without melting or softening, which avoids the pollution caused by damage; In addition, the coefficient of thermal expansion is low, and the thermal shock resistance is good, which is also conducive to avoiding pollution caused by thermal shock cracking. Therefore, the mullite crucible tray is particularly suitable for the calcination of impurity sensitive materials, such as high-purity alumina, lithium battery materials.