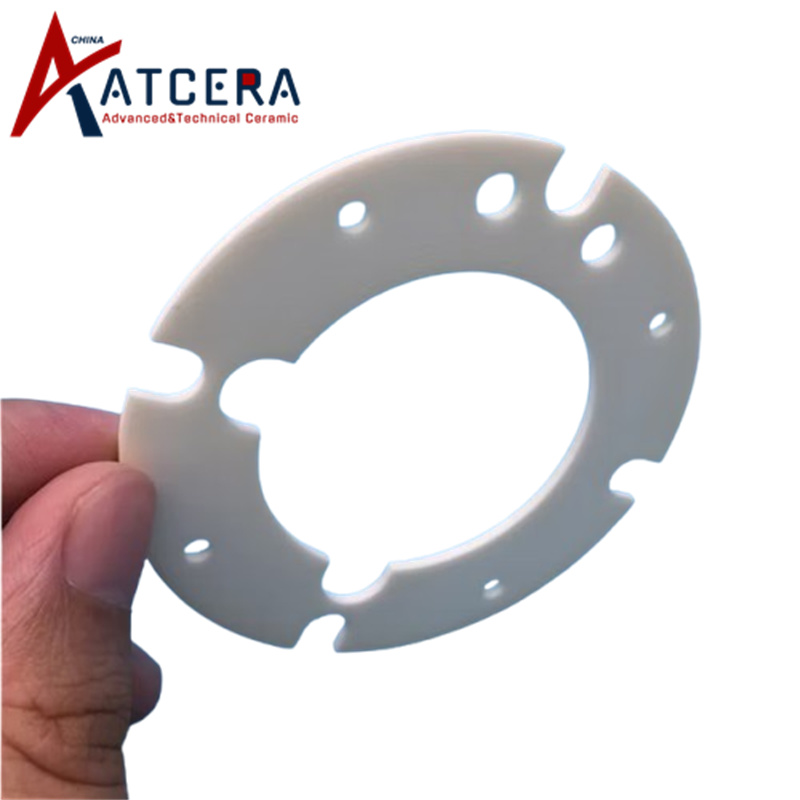

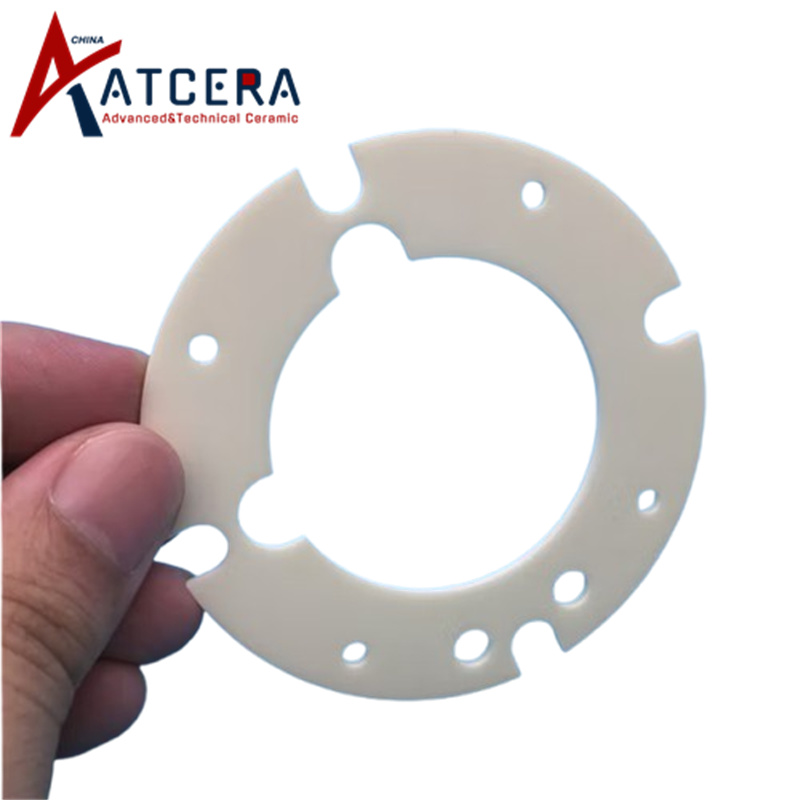

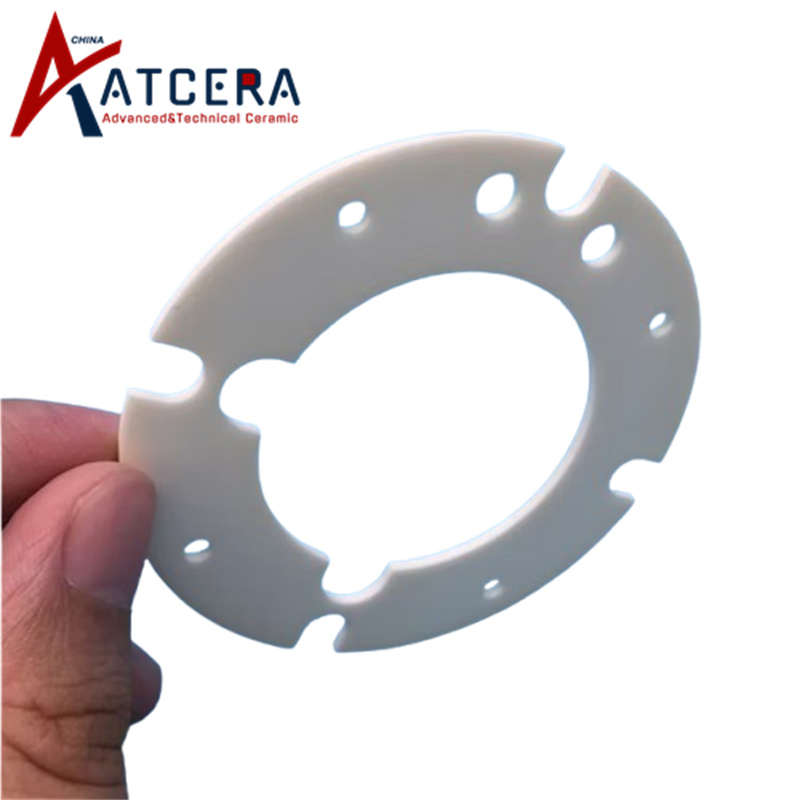

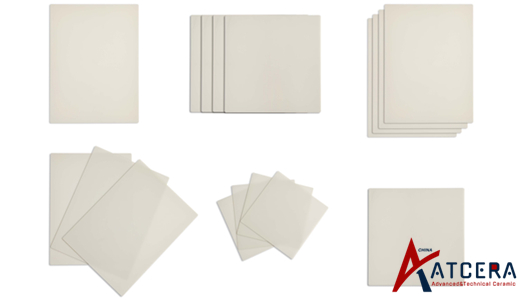

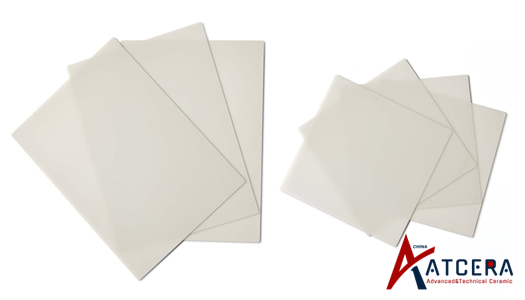

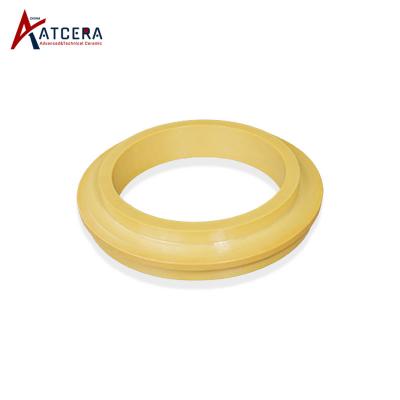

Properties of Aluminum Silicate Ceramic Fiber Insulation Gasket

1. Tough & Wind Erosion Resistant

The Aluminum Silicate Ceramic Fiber Insulation Gasket is designed with superior toughness and exceptional wind erosion resistance, making it ideal for use in harsh industrial environments. It offers long-lasting performance even in the most demanding applications, such as furnaces and kilns.

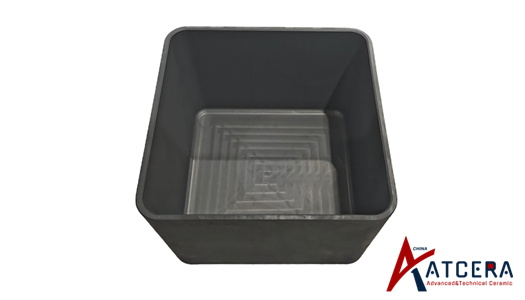

2. Seamless Furnace Lining

This ceramic fiber insulation gasket forms a seamless and efficient furnace lining, preventing gaps and improving overall insulation performance. It ensures optimal thermal protection and contributes to energy savings by minimizing heat loss in industrial heating systems.

3. Low Heat Retention & Reduced Heat Loss

With low heat retention, the Aluminum Silicate Ceramic Fiber Insulation Gasket significantly reduces heat loss, helping to enhance energy efficiency in furnaces, kilns, and other high-temperature applications. Its low thermal mass makes it a cost-effective solution for thermal management.

4. Direct Flame Contact for Hot Surfaces

This insulation gasket can be used for direct flame contact in high-temperature applications, providing a reliable solution for insulating hot surfaces without compromising performance. Its ability to withstand direct exposure to flames makes it highly versatile for industrial use.

5. Excellent Installation & Construction Performance

The Aluminum Silicate Ceramic Fiber Insulation Gasket is easy to handle, cut, and install, making it an ideal choice for quick and efficient construction or retrofit applications. Its user-friendly installation process ensures minimal downtime and labor costs.

6. Superior Thermal Shock Resistance

This ceramic fiber gasket offers outstanding thermal shock resistance, allowing it to perform well under fluctuating temperatures. It ensures consistent and reliable insulation even in environments with rapid temperature changes.

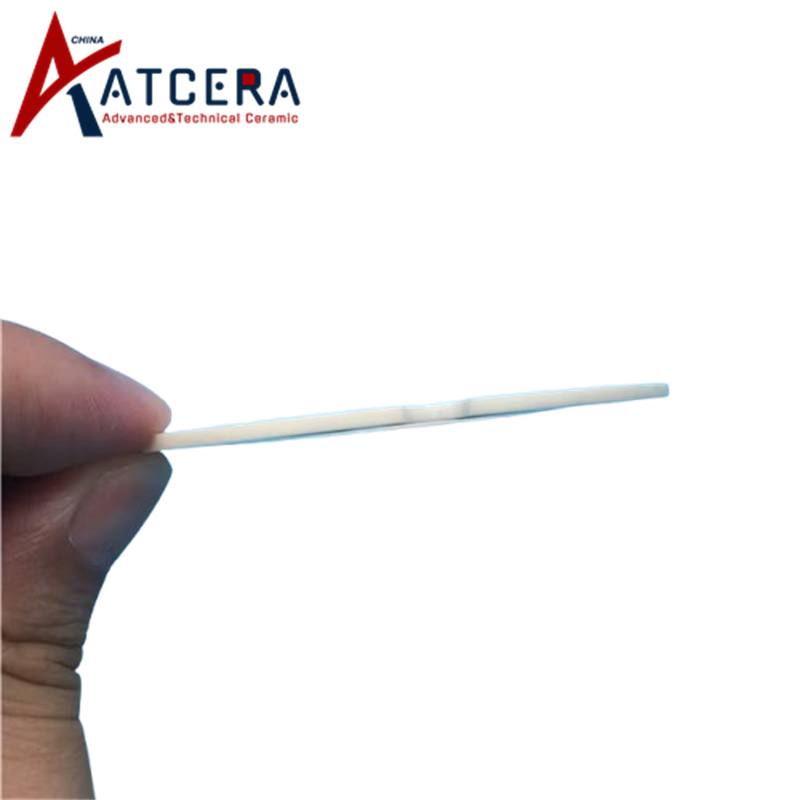

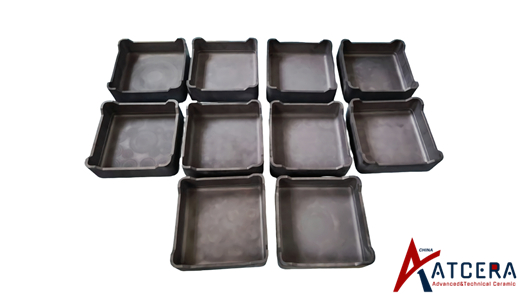

7. High Compressive Strength & Long Service Life

Built to withstand high pressure, the Aluminum Silicate Ceramic Fiber Insulation Gasket provides exceptional compressive strength and has an extended service life, even under extreme operating conditions. It reduces the need for frequent replacements, offering excellent value for money.

8. Effective Sound Absorption

In addition to its thermal insulation properties, this insulation gasket features outstanding sound absorption capabilities, making it ideal for noise reduction in industrial applications. It helps maintain a quieter, safer working environment in facilities like power plants and manufacturing plants.

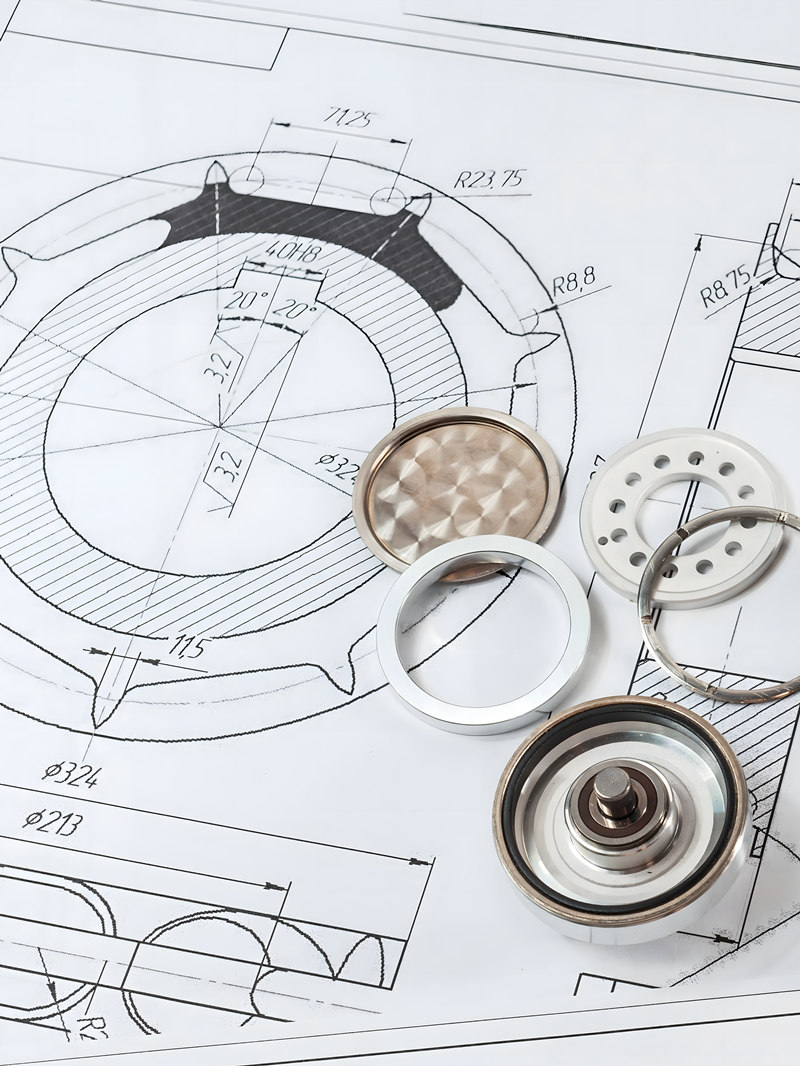

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.